CW Morgan at Mystic with a whaleboat in the foreground.

A raised lofting table was constructed in the school's loft for the whaleboat.

Lofting details

Deciding if the lines are fair

Freshly steamed stem being inserted into the bending jig and bent to shape using a compression strap.

Stem secured in bending jig. Note the custom fabricated compression strap attached to the jig at one end and the handle at the other end.

Chopping the rabbet into the stem

Construction of the backbone begins

Building jig is erected, backbone assembled, and molds are secured in place.

Garboard plank hung along with a lapped-straked plank above it on the starboard side. The following planks will be done with carvel batten-seams.

Bottom two planks on the port side completed. Note the notches in the molds for the batten seams that were laid out during the lining off process.

The whaleboat seen amongst all the other developing projects in the shop.

First lapstrake plank below the sheer being hung.

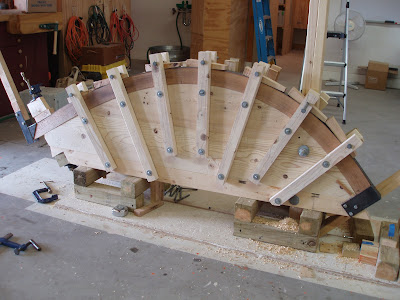

Students slowly bend the a frame over the jig using a compression strap.

Steamed frames are drying in bending jig as planking work continues.

With the completion of planking, work shifts to installation of the pre-bent frames.

Clamping the frames in place.

All images courtesy Great Lakes Boatbuilding School

"The Great Lakes Boat Building School (GLBBS) is proud, honored, and excited to have a role in the Mystic Seaport museum’s restoration of the Charles W. Morgan."

So begins the glbbs short dissertation on the project, with a history of the Morgan, a nicely done description of the whaleboat in general and the Beetle craft in particular and a statement of their expectations and the merit of taking on such a project. As with most of the participants in the project, Great Lakes is using the build as a learning experience for their students. Indeed, their website outlines in great detail what the students will be learning. Here is a taste of that:

"First and foremost, in the building of this whaleboat students will learn team work. It has been said, “To work with someone is to know him; to build a boat with him is to know him well.“ And so it goes at GLBBS.

The process begins with the preliminary work being done by second-year students, while the first-year students are being introduced to classic woodworking skills, which involves building their toolboxes and being introduced to the fundamentals of lofting. Second-year students, having learned the required lofting skills in their first year, will loft the whaleboat to establish its full-size lines, which then will be used to form the necessary references and patterns required for accurately building this boat to the Beetle design.

Second-year students will continue on with the next step, which is using the lofting lines to make the molds representing the hull shape, then setting the molds up in a building jig. The building jig is designed for building the whale boat right-side up, and also to allow plenty of height underneath for working on the bottom of the whaleboat.

Once the second-year students have completed the building jig, the actual boat construction begins with the building of the backbone. They will build a keel, stem, and sternpost. In this process, they will gain more experience in constructing a bending jig, as well as the steam bending process involved in bending the stem and sternpost. When the stem and stern post have been bent to shape, students will learn how to layout and carve the rabbet into the stem and sternpost and assemble them together on the building jig to form the backbone of the whaleboat."

Suffice it to say, there's a lot more.

My sincere thanks to Kevin Pagliuca at Great Lakes for his assistance.

.JPG)

No comments:

Post a Comment